Edge banding machines have become essential in woodworking and furniture manufacturing, providing a practical solution for finishing raw panel edges. These machines apply a thin strip of material—known as edge banding—to cover the exposed sides of panels, improving durability and aesthetics. This article delves into the fundamentals of edge banding machines, their types, and the key features that define efficient operation, focusing particularly on the advantages of the automatic edge banding machine.

What Is an Edge Banding Machine?

An edge banding machine is a specialized piece of equipment used to apply edging materials such as pvc, ABS, wood veneer, or melamine tape to the edges of panels made from plywood, particleboard, or MDF. The purpose is to seal the edges, protect the panel from moisture, and enhance its visual appeal. Edge banding machines vary from manual to fully automatic systems, with the automatic edge banding machine capable of completing all steps—including gluing, pressing, trimming, and buffing—without manual intervention, ensuring consistent quality and increased productivity.

Key Features of Automatic Edge Banding Machines

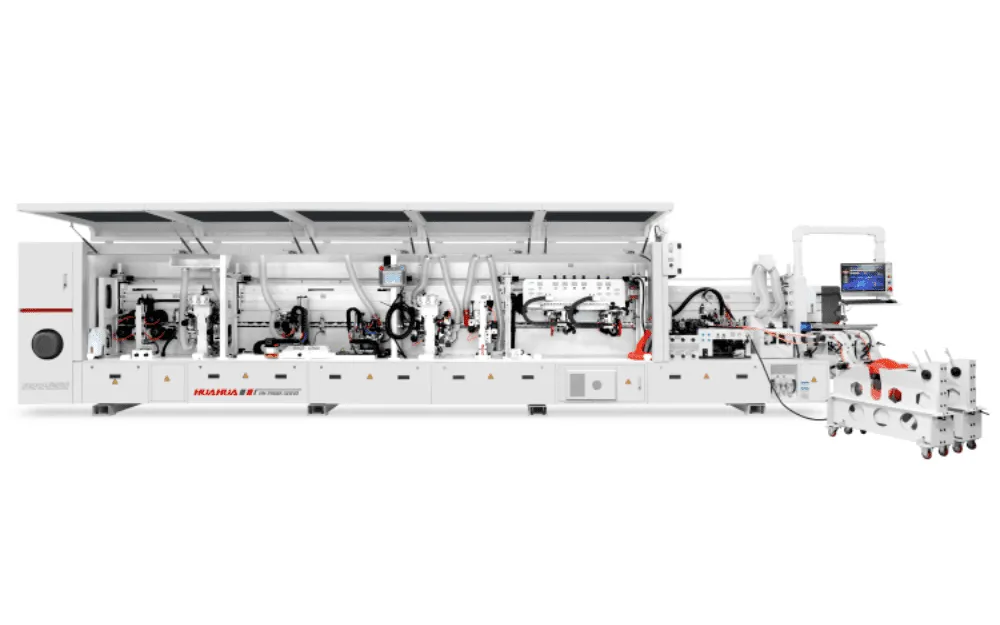

The automatic edge banding machine integrates multiple processes into one streamlined operation. It typically includes functions such as edge feeding, glue application, trimming, and polishing. Advanced models feature servo motors for precise control and adjustments, which improve accuracy and reduce waste. For example, the HH-796RK-SERVO model offers a large computer screen with a user-friendly interface and servo adjustment guide plates, making it easier to operate and fine-tune settings. Additionally, the machine accommodates a panel thickness range and corner rounding capabilities, which add versatility for different project requirements.

Advantages in Woodworking and Furniture Manufacturing

The use of an automatic edge banding machine significantly improves productivity and finish quality in woodworking. By automating the edge banding process, manufacturers reduce labor costs, minimize human error, and increase throughput. The precise application of edge banding materials ensures a durable, seamless finish that enhances both the functionality and appearance of the final product. The ability to handle different panel thicknesses and edge profiles makes these machines essential in customized furniture production and large-scale manufacturing.

Enhancing Woodworking Efficiency with HUAHUA CNC

HUAHUA CNC offers advanced edge banding solutions such as the HH-796RK-SERVO, designed to meet the demands of modern woodworking industries. With its compact size (9.551.12m), wide panel thickness range, and corner rounding capabilities, the machine supports diverse applications. The integration of a large computer screen and servo motor technology provides operators with enhanced control and ease of use, boosting operational efficiency. HUAHUA CNC’s commitment to innovation ensures that their automatic edge banding machines contribute reliably to precision and productivity in panel processing workflows.